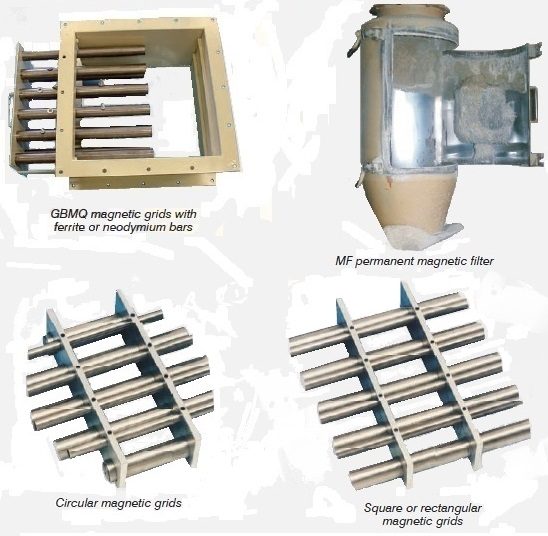

Magnetic filters and grids

Hight intensity separators

Tubular magnetic filter MF and EF

The tubular magnetic filter MF (by permanent magnets) and EF (by electromagnets) are magnetic separators which, located vertically along the fall of some granular or powder material, attract and hold inside ferrous material, leaving inert material go through. These filters are particularly suited to separate accidental intrusions, which could jeopardise the product itself or machines located downstream.

The permanent version MF needs periodic manual cleaning operation.

The electromagnetic version EF is often coupled to a pneumatically operated valve (optional) in order to discharge iron pieces out of the vertical falling line.

OPERATION PRINCIPLE

The tubular magnetic filters are essentially made up by two parts:

- An external flanged tube with a tight door, in stainless steel AISI 304,

- An internal magnetic core fixed to the door, for models MF1, MF2 and MF3.

The core is fixed to supports in AISI 304 in all other models.

Above the magnetic core a cone is arranged, in order to distribute the process material on the magnetic poles. The cone vertex is directed upward. The tubular magnetic filters must be installed vertically to grant their rate flow, separation efficiency and material cleaning. The falling material goes through the magnetic field and iron scraps are attracted and hold by three magnetic poles. In order to clean the filter, the material must be stopped and cleaning must be carried out manually for MF filters or electrically for EF filters.

Magnetic Grid