Air Separator Zig Zag

The air required for this separation process

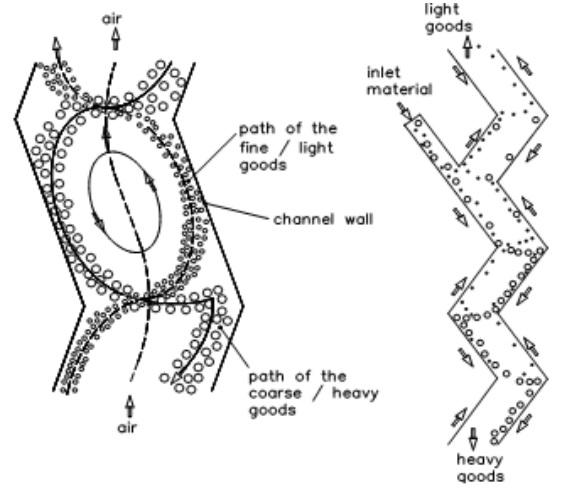

The starting material is conveyed into the zig-zag shaped sifter channel through an airtight feed mechanism. Here, lighter materials are separated from heavier ones using a multiple cross-flow sifting process.

The air required for this separation process flows from bottom to top through the sifting channel. The lighter particles are swept away with the air current while heavier particles fall toward the bottom against the flow of air and are discharged at the base of the separator.

The light material carried by the air flow exits out the top through the sifter channel and is conveyed via ducts to the cyclone where it is then separated and discharged through a rotary gate valve. In general, zig-zag air separator systems operate in recirculation mode, where a ventilator blows the purified air back into the base of the separator. For very dusty or moist products it is also possible to operate the system in partial recirculation or suction mode. The required air flow is provided by a radial ventilator.

APPLICATIONS:

- Household and Industrial

- Waste Construction Waste

- Electronic Scrap Slag/Ash

- Shredder Scrap

- Tires Recycling Glass

- ASR Substitute Fuel

ADVANTAGES:

- High-precision separation due to multistage crossflow process (8 to 15 separation stages); also pro duces uniform sifter cross-sections for post-sepa ration of light materials.

- Desagglomeration and breakdown of light material clusters.

- Stable operation through a specially designed fan wheel.

- Maintenance hatches in the sifter channel for quick cleaning.

- Recirculation function means no emissions.

- Robust construction and no rotating parts in the separator leads to high availability levels.

- No rotary gate valve necessary at the sifter input or output for heavy products; this is dealt with by a special conveyor feeder with rubber curtains

- Up to 2-m working width.

OPTIONS:

- Up to 15 separation levels

- Turnkey plant solutions possible

- Feed hopper

- Custom configurations possible