Roller mill

Economic crushing of feed mixtures, cereals, legumes and oilseeds

HOW DOES A KAHL CRUSHING ROLLER MILL WORK? WE WILL SHOW YOU!

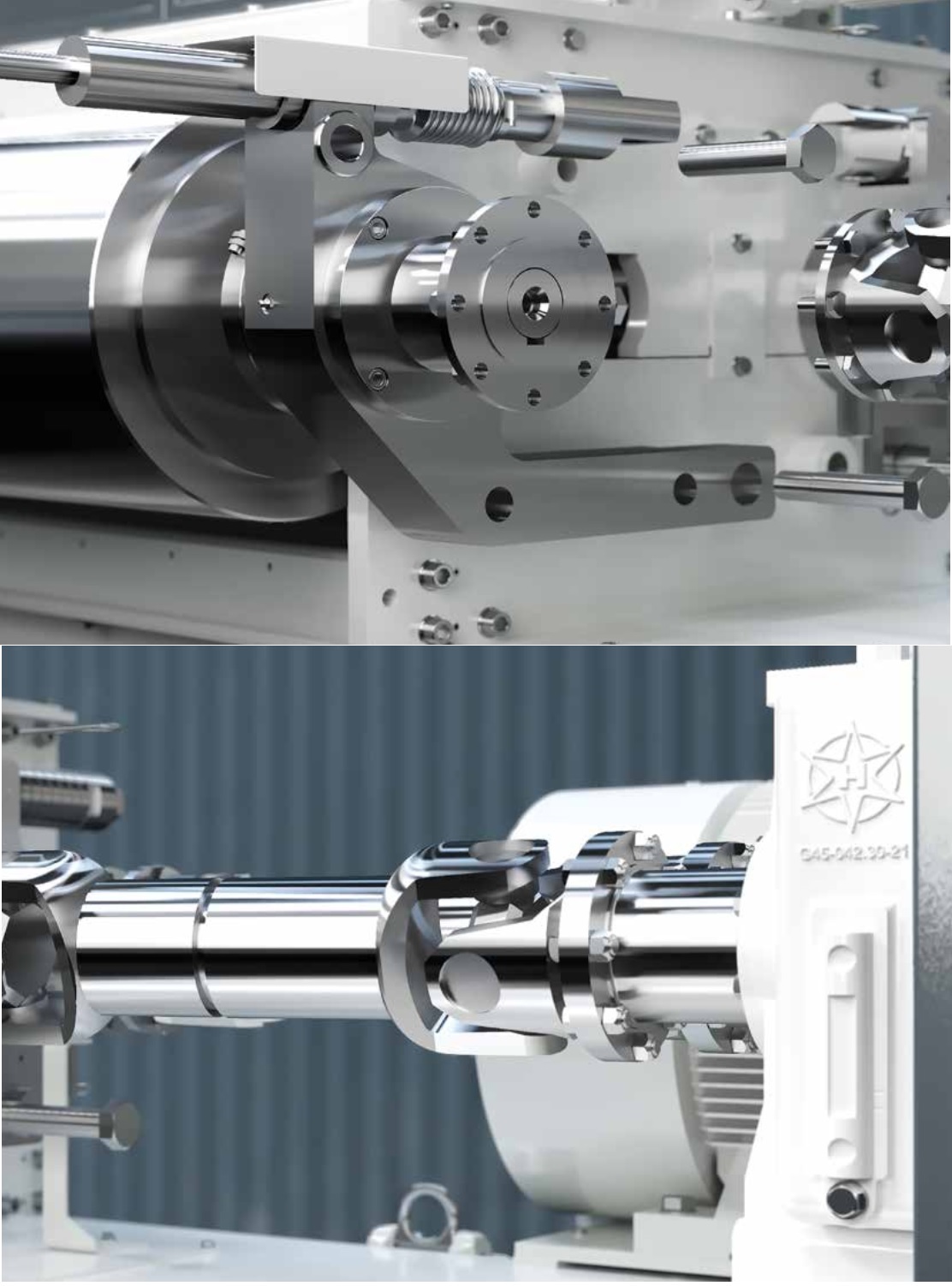

Animal nutrition research findings have shown that not only the formula and the ingredients contribute to the feeding success, but also the feed structure. KAHL crushing roller mills break the grain into smaller particles with an as low as possible fines content. Granular crumbles with a low fines content are produced instead of meal. The crushing rollers are provided with a “sharp to sharp” corrugation and have different speeds so that a cutting effect is obtained instead of a crushing effect. The speed of the rollers and the grinding gap can be adjusted during operation. The KAHL crushing roller mill WSB is very appropriate for economic grinding of different products, particularly for grain and other feed components.

• Two counter-rotating rollers

• Differential speed of the two rollers

• Defined gap between the rollers for specific particle size reduction

• Crushing by a combination of shear stress, cutting and pressure

• Special corrugation of the rollers, individually adaptable

• The roller diameter influences the product feeding and the size of the grinding zone

• Multi-stage grinding with upstream screening for an optimized particle size distribution