Eddy Current magnetic separator

Widely used in the field of recycling glass, wood, waste, plastic

EDDY CURRENT MAGNETIC SEPARATOR ECSE

EDDY CURRENT MAGNETIC SEPARATOR ECS

In order to meet the growing demands of the market and improve the quality of the separated material, Gauss Magneti has introduced in its production the eccentric eddy current separator ECSE.

The eddy current separators ECSE are machines employed for the separation of non-ferrous material especially of small dimensions (aluminum, copper, etc.), from the inert material (glass, plastic, wood, etc.).

Principle of operation

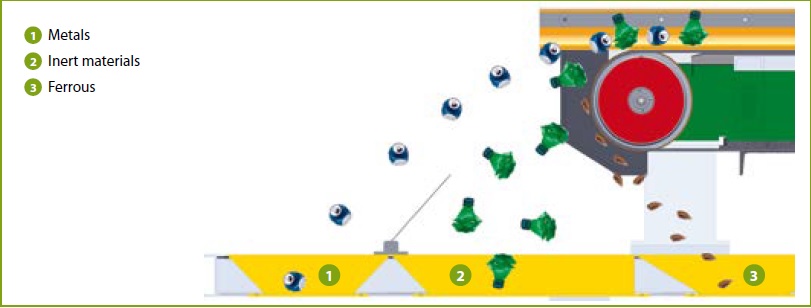

The principle of operation is based on the action of eddy currents generated in the non-ferrous metals, by a high-frequency alternating magnetic field. The metal is separated from inert by repulsion.

The belt carries the process material over the inner magnetic rotor, where the nonferrous is launched forward, while the inert falls freely.

Peculiarity of this separator is the eccentric rotor. The advantage is the concentration of the magnetic field in a particular area of the rotor, where it reaches the maximum intensity. This specific force modifies the trajectory of the non-ferrous material.

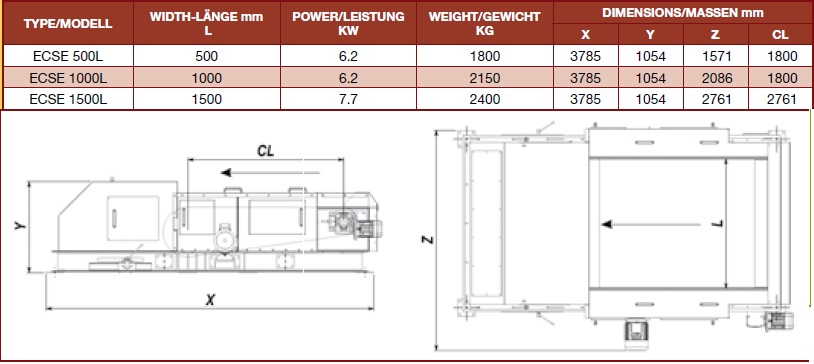

This separator is available with widths of 500 – 2.000 mm.

BELT SPEED – 1,5 ÷2,5 m/s

ROTOR SPEED – ≤ 4200 RPM

FREQUENCY – ≤ 1,5 kHz

MATERIAL SIZE – 2 ÷ 10 mm

The ECS are widely used in the field of recycling glass, wood, waste, plastic, etc., thanks to their effectiveness in separating non-ferrous metals and alloys from inert material.

Principle of operation

The principle of operation is based on the action of eddy currents generated in the non-ferrous metals, by a high-frequency alternating magnetic field. The metal is separated from inert by repulsion. The belt carries the process material over the inner magnetic rotor, where the nonferrous is launched forward, while the inert falls freely.

The quality of separation, offered by these machines, is directly proportional to the ratio between the electric conductivity and the specific weight of the material to be separated.

Gauss Magnets, thanks to its deep experience in this matter and to its attention to customer requests, has improved, over time, the design of these separators and now offers various working widths (500 – 2.500mm), to meet the different separation requirements.

Which performances can be obtained using ECS:

The performance may be bound by the use conditions and by the nature of the material (size homogeneity, humidity, temperature, etc.); in the best conditions, it is possible to obtain:

- Separation of ferromagnetic intrusions 99.9%, thanks to the concentric magnetic rotor;

- Separation of non-ferrous metals from 93% to 99%;

- non-ferrous separated metals purity by 80% to 95%.

BELT SPEED – 1,5 ÷3,5 m/s

ROTOR SPEED – ≤ 4000 RPM

FREQUENCY – ≤ 1000 Hz

MATERIAL SIZE – 2 ÷ 350 mm, uniform and consistent