Groeneveld-BEKA group is a leading manufacturer of automatic maintenance systems.

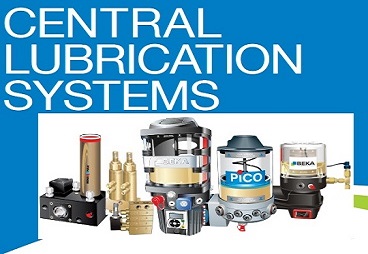

CENTRAL LUBRICATION OVERVIEW

Groeneveld-BEKA group supplies automatic central lubrication systems for many industrial applications.

Centralized lubrication systems for industrial applications

Groeneveld-BEKA develops and produces industrial lubrication systems of all kinds, like single line systems, multi line systems, progressive systems, dual line systems, oil circulating systems and oil/air systems. A large range of gear pumps completes this comprehensive program

Centralized lubrication systems for mobile applications

The BEKA-MAX product range has been developed for all mobile applications. All products are designed with the durability required for harsh environment found on trucks, agricultural and construction machinery. These progressive systems are designed to handle standard grease.

Wheel flange lubrication and rail head maintenance system

With rail vehicles, wear on the wheels and the rail itself is a major problem together with the noise generated. The application of a FluidLub system using thixotropic lubricating media with a high solids content represents the solution to these problems.