Magnetic drums

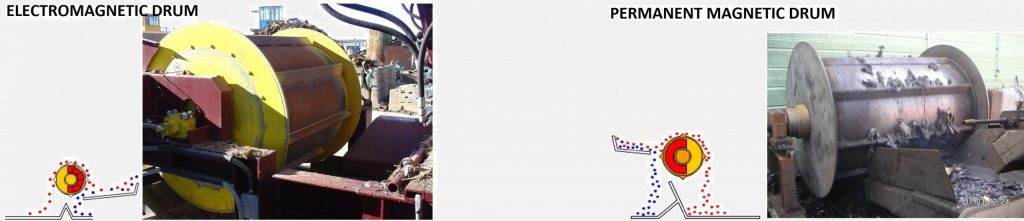

Magnetic field can be created by electric or permanent magnets

Suitable for automatic and continuous separation of ferrous material in small, medium, and large sizes, they are installed on the conveyor discharge, whether they consist of bands, slides, or vibrating channels.

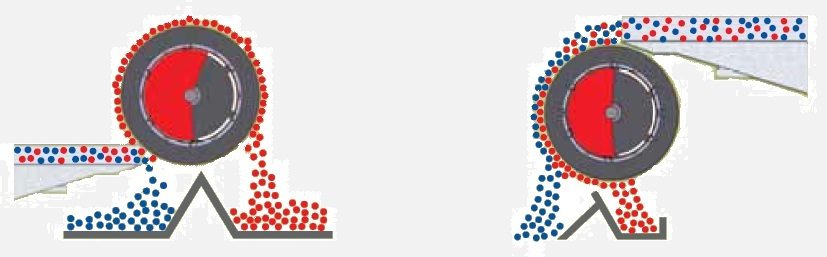

The magnetic drums, with magnetic field spread on 180°, catch the ferromagnetic parts in the material by deviating their direction from that of the processed material.

The constant and homogeneous material distribution is important in the use of magnetic drums.

The magnetic drums are made by:

- The magnetic core, thanks to the adjustment possibility, is fixed at a certain position to capture the ferromagnetic material in the processed material. Magnetic field can be created by electric or permanent magnets, Ferrite, Neodymium, or in special cases, such as high or low temperature operations, with magnets made of special alloys.

- The rotating drum shell is made of non-magnetic material; it rotates around the magnetic core, supported by lateral flanges, by evacuating the ferromagnetic material attracted over the magnetic field.

Magnetic drums can pick up considerably heavy and quite large ferrous pieces, but it is also ideal to separate materials of small dimensions.

As for the extraction of the ferromagnetic material from the process, our magnetic drum can have two different magnetic configurations, with a longitudinal polarity (O) or a radial polarity (V). These can then be constructed with permanent magnets (Ferrite, Neodymium) having a constant intensity, or with electric windings (aluminium, copper) to be able to vary the magnetic intensity to obtain different degrees of separation of the processed material.

The use of the drum magnetic polarity allows a longitudinal magnetic separation thanks also to the tumbling of the material during the shell rotation. The tumbling consists in the rolling of the material thanks to the geometry of the magnetic field.

Fields of application are numerous: metal processing recycling plants, WEEE, waste processing and recycling, minerals, wood, glass, sand, and aggregates, etc…

Every single case submitted to us will always be examined by our technical department, who will propose the correct solution to your problem.

Some data:

External diameter – ø400 – ø2000 mm

Size of the process material – 10 – 300 mm

Width – 400 – 3000 mm

Some data:

External diameter – ø 200-2000 mm

Size of the process material – 1-300 mm

Width – 200 – 3000 mm